EQUIPMENT – GEMLAB FURNACE SPECIFICATIONS

Based on our 40 years experience involved in the gemstone treatments we have concluded that the best design for heating up to 3200 carats of ruby-sapphire and other colored gemstones to 1700°C is to use the vertical muffle configuration. After many years of research and experimentation, these furnaces are designed and fabricated in our workshop-laboratory in Bangkok based on the key parameters required for every heating process: temperature profile, atmosphere conditions, and chemical additives).

Model M80P-1700 Bottom-loading vertical alumina tube muffle furnace to 1720°C

Model M50P-1700 Bottom-loading vertical alumina tube muffle furnace to 1720°C

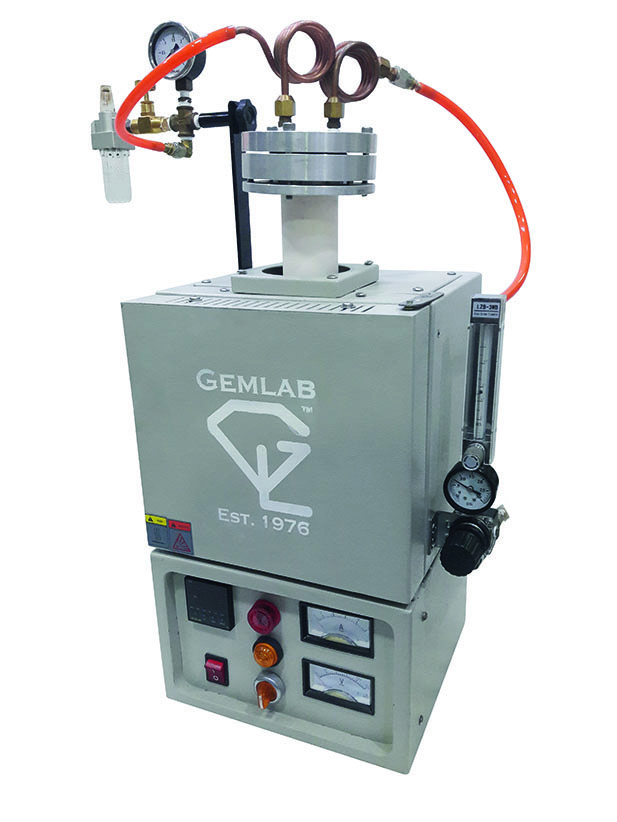

Models BV50, V50 SERIES Top-loading vertical alumina tube muffle furnace to 1300°C

Gemlab’s models BV50-1200, BV50-1300, V50-1200, V50-1300 are lightweight desktop furnaces that stand out with their unique design, occupying the minimum workspace. They are the most economical furnaces designed by Ted Themelis. The furnaces are top-loading vertical muffle furnaces, employing unparalleled versatility and an impeccable design that sets them apart in the industry. Each furnace model is composed of an integrated heating module, temperature and power control, single-gas purging and exhaust assemblies. Suitable gemstones may be loaded and heat-treated for days, weeks or months in various atmospheres, with or without chemical additives, or even in a vacuum.

GEMSTONE HEATING PRACTICAL APPLICATIONS USING GEMLAB FURNACES

LOW TEMPERATURE: The following gemstones are suitable for heating to alter their color: Apatite, beryl, demandoid, fluorite, moonstone an other feldspars, pearl, peridot, quartz, scapolite, spodumene, tanzanite, topaz, tourmaline, zircon. The process uses the muffle module with/without single gas purging at any temperature heating profile. The following models are available: Model BV50-1200, temperature 1100°C with small capacity. Model V80-1200 for temperature 1100°C large capacity. Model BV50-1300, temperature 1300°C, small capacity. Model V80-1300 temperature 1300°C, large capacity. Consult Ted Themelis’ book “Gemstone Treatments” descussing the heating processes performed using the low-temperature GEMLAB furnaces in the following practical applications:

- Heating in air, oxygn, argon, nitrorgen with muffle, with/without flux compositions (800°C-1300°C); also in vacuum

- Lithium Carbonate Process on selected types of corundum (800°C-1300°C)

- PbO-based fracture filling process of ruby-sapphire; also PbO+CoO process (usually 900°C-1200°C+).

- Quench crackled process on synthetic ruby-sapphire (400°C-800°C)

- Post-irradiation heating process of diamond, beryl (aquamarine, morganite), chrysoberyl, quartz, topaz, tourmaline

- Closed Buffering Carbon Cell (CBCC) process producing reducing atmosphere for heating zircons and some sapphires.

HIGH TEMPERATURE: Heating ruby-sapphire with/without gas purging buffering and non-buffering chemical reaction processes at any temperature heating profile. GEMLAB high temperature furnaces are suitable for the following practical applications:

- Color alteration and/or fracture filling of any treatable type of ruby-sapphire (1450°C-1700°C).

- Heating with flux compositions (usually above 1300°C)

- Lithium Carbonate Process on selected types of corundum (above 1300°C)

- Exsolved rutile "removal" in ruby-sapphire using GEMLAB's unique technique (usually 1450°C-1625°C)

- Surface Color Diffusion process (usually 1300°C-1500°C)

- Surface Asterism Diffusion process (usually 1600°C-1700°C)

- Beryllium Process (usually 1625°C-1650°C)

Model M50-1700 (low capacity), model M80-1700 (high capacity. These models are suitable for heating using flux compositions for fracture-filling clarity improvement. Heating lower than 1450°C for a long soaking time is not recommended to preserve the MiSiO2 heating element’s longevity. Consult Ted Themelis’ monographs on heating ruby-sapphire.